FRP Pultruded

Gratings

Pultruded Fibre-Reinforced

Polymer Grating Systems for

Load-Bearing Industrial and

Infrastructure Zones

Edoburg supplies structurally reinforced FRP Pultruded Gratings engineered for long-span, high-load, and chemically aggressive environments. Manufactured using continuous pultrusion of glass fibre reinforcements with thermosetting resin matrices, these gratings offer superior mechanical strength, corrosion resistance, and fire-safe performance for infrastructure-grade applications.

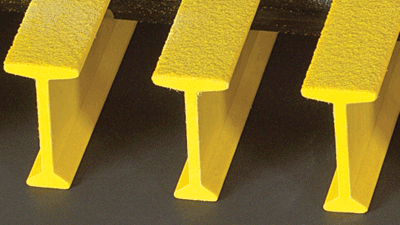

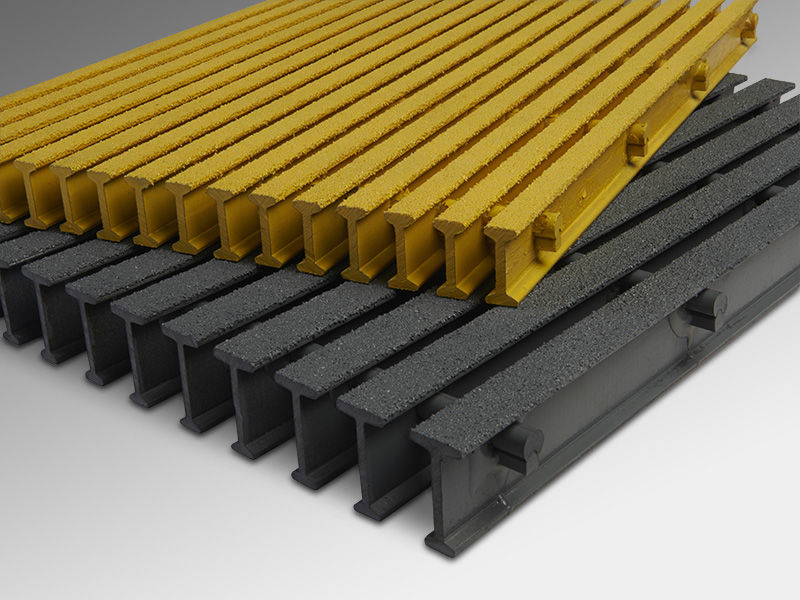

Whether for chemical plants, oil platforms, or utility walkways, our pultruded gratings are offered in I-bar and T-bar configurations, with slip-resistant surfaces, UV protection, and industrial-grade tolerances.

All panels are export-ready, documentation-compliant, and dimensionally pre-mapped as per project BoQ and structural layout.

Ideal Range

High-strength, corrosion-resistant pultruded grating systems engineered for long-span stability, chemical exposure tolerance, and structural safety across industrial, marine, and infrastructure-grade environments.

High-Load Pultruded I-Bar Grating

Fire-Retardant T-Bar Grating Panels

Long-Span Pultruded Walkway Grating

Products That

Matters

Available Specifications

-

Bar Types: I-Bar / T-Bar Profiles

-

Load Rating: Up to 5 tonnes/m²

-

Panel Sizes: 1000 × 3000 mm and custom

-

Open Area: 30% to 60%

-

Resin Types: Isophthalic, Vinylester, Phenolic

-

Surface: Concave / Grit-top anti-slip

-

Colour Options: Yellow, Grey, Green (UV-stabilised)

-

Fire Rating: ASTM E84 Class 1

-

Standards: ANSI/NAAMM FG-P-2020, EN 13706, ISO 9001

Applications

-

Power plants and transformer yards

-

Industrial access platforms and walkways

-

Loading bays and trench covers

-

Petrochemical zones and marine decks

-

MEP utility corridors in EPC projects

-

Wastewater and corrosive chemical sites